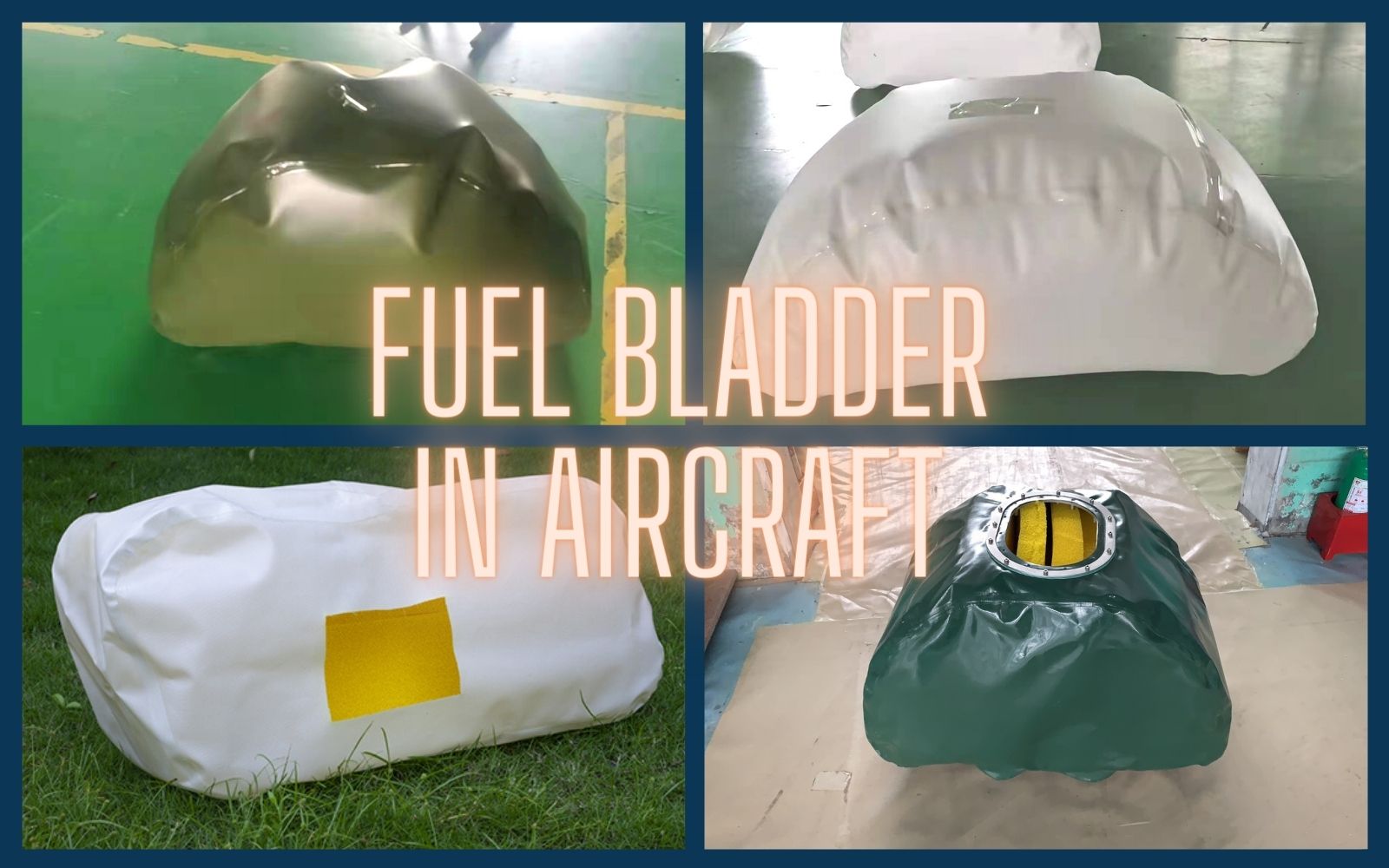

Using flexible fuel tanks in aircraft for several reasons:

Flexible fuel tanks designs to fit into unused spaces within the aircraft, allowing for increased fuel capacity without requiring modifications to the aircraft’s structure. This can increase the aircraft’s range and/or reduce the need for refueling stops.

Compared to traditional fuel tanks made of metal, flexible fuel bladders are lightweight and shaping to fit into available spaces in the aircraft, reducing the overall weight of the aircraft.

Flexible fuel tanks are less prone to explosion and fragmentation compared to traditional metal fuel tanks. In the event of a crash, the flexible material of the fuel bladder can absorb impact and reduce the risk of fire.

Flexible fuel bags design to fit the specific shape of an aircraft, allowing for maximum use of available space. Size ranges to meet the specific needs of an aircraft.

Flexible fuel bladders are typically made from high-quality materials that are resistant to punctures and leaks. This helps ensure that the fuel remains contained and safe during flight.

Flexible fuel bags are typically less expensive to manufacture than traditional metal fuel tanks, making them a cost-effective option for aircraft manufacturers.

Overall, flexible fuel tanks offer several advantages over traditional metal fuel tanks, including increased fuel capacity, reduced weight, improved safety, and cost-effectiveness.