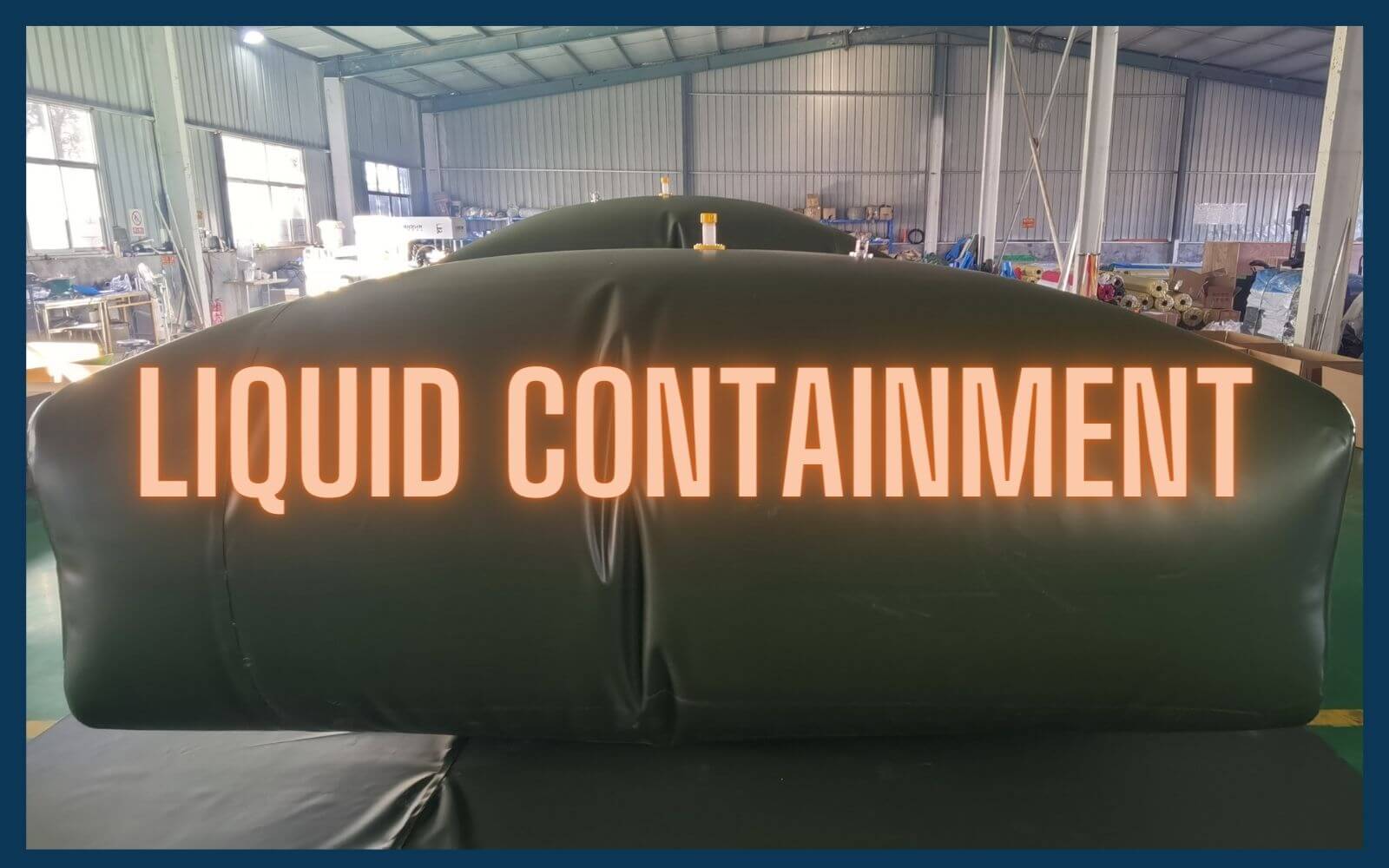

LIQUID CONTAINMENT

In today’s industrial, agricultural, commercial industries, the demand for efficient liquid containment solutions grow. Flexible bladder tanks have emerged as a versatile and practical option for storing various liquids, including water, fuel, and chemical liquids. Let’s dive into to explore the world of flexible bladder tanks and their wide-ranging applications.

Flexible liquid containment(bladder tanks), also name as pillow tanks or collapsible tanks, are innovative storage solutions designed to long-term or temporary store or transport liquids safely. These tanks typically use durable materials such as PVC or TPU fabrics, and the feature a flexible structure that expands as it fills to fit the shape of bladder with liquid. This unique design allows them to use in limited space with wide range capacity.

Flexible bladder tanks find applications across a multitude of industries due to their versatility and reliability. They are commonly used for:

Water Storage:

Flexible bladder tanks are ideal for storing potable water, rainwater harvesting, and firefighting water storage.

Fuel Storage:

From gasoline(including JP-8) and diesel to lubricating oil, flexible bladder tanks offer a safe and efficient solution for fuel storage in remote locations or emergency situations.

Chemical Storage:

With their chemical-resistant properties, bladder tanks are suitable for storing a wide range of chemicals, including acids, alkalis, and other hazardous liquids.

The use of flexible bladder tanks offers several advantages:

Versatility:

The bladder liquid containment shows the flexibility in 2 main methods:

The compatibility:

The flexible tank can use to store water, fuel, chemical liquids which can meet the compatible requirement for each types. The robust PVC materials often use for wastewater storage for treatment or storage and also for chemical(including acid/alkalis liquid).

TPU(food-grade) use for drinking water storage and transportation, which meets the FDA certificate.

TPU(for fuel) which is compatible for fuel liquid, widely use as fuel bladders in industries, like on boat, marine, fuel station, even aviation(JP-8).

The custom available:

When we say the custom service, it means the every detail on the bladder. You can custom the materials, shape, size, fittings, according to the drawings which should be processed by the specific requirement from the working site.

Cost-effectiveness:

Compare with the traditional liquid containers, the flexible tanks can save money from 3 ways:

- The initial cost, bladders can save half price comparing with the stainless steel.

- The shipping cost, what is the cost of arranging the shipment for a 1000L tank? For PE tank, the 1000L tank, the packing size is at least 1m3, but bladder tank, the packing size of the 1000L is only 0.2m3.

- Installation cost, the installation of bladder tank can be fast: unfold, filled, done.

Maintenance:

The feature of the material provides some advantages to the soft bladders, UV-resistance, anti-bacterial, anti-corrision. So there have many methods to maintain those tanks, easier and cheaper ways.

Buying a flexible liquid containment, factors to be considered:

- Do you need the custom service?

This is the first question you should think about, do you have specific requirement, about the shape, size, fittings?

The standard configuration:

Shape, the regular shape includes the pillow shape and the rectangular shape.

Capacity, size ranges from 100L to 1,000,000L, regular size: 1000L, 2000L, 5000L, 10,000L, 20,000L, 40,000L, 100,000L, 200,000L, etc, others can be customized.

Beside those above, the working places should consider into, different working condition the fittings may be different. So contact with supplier to make sure if the custom containment needed.

- What will you use for?

For different liquid storage, the material is different, as the compatibility should be accounted into, when we choose bladders.

- What capacity needed?

Providing the loading capacity to factor, then we will recommend the suitable capacity to you with size. Or offering the exact dimension to the supplier to make the specific size happened.

- Environmental conditions:

The working condition is also necessary to consider, the flexible material(PVC/TPU), mostly the working temperature: -40~90 c degree.

And adding UV-resistance raw material into is default, but this feature can custom too. If containments are working indoor, we can remove it.

- Others:

Regulations and Compliance: Adhere to relevant regulations and standards governing the storage of specific liquids, especially hazardous chemicals.

Flexible bladder tanks offer a versatile and efficient solution for liquid containment across a wide range of applications. Their customizible design, cost-effectiveness, and durability make them an indispensable asset for industries requiring reliable storage solutions.