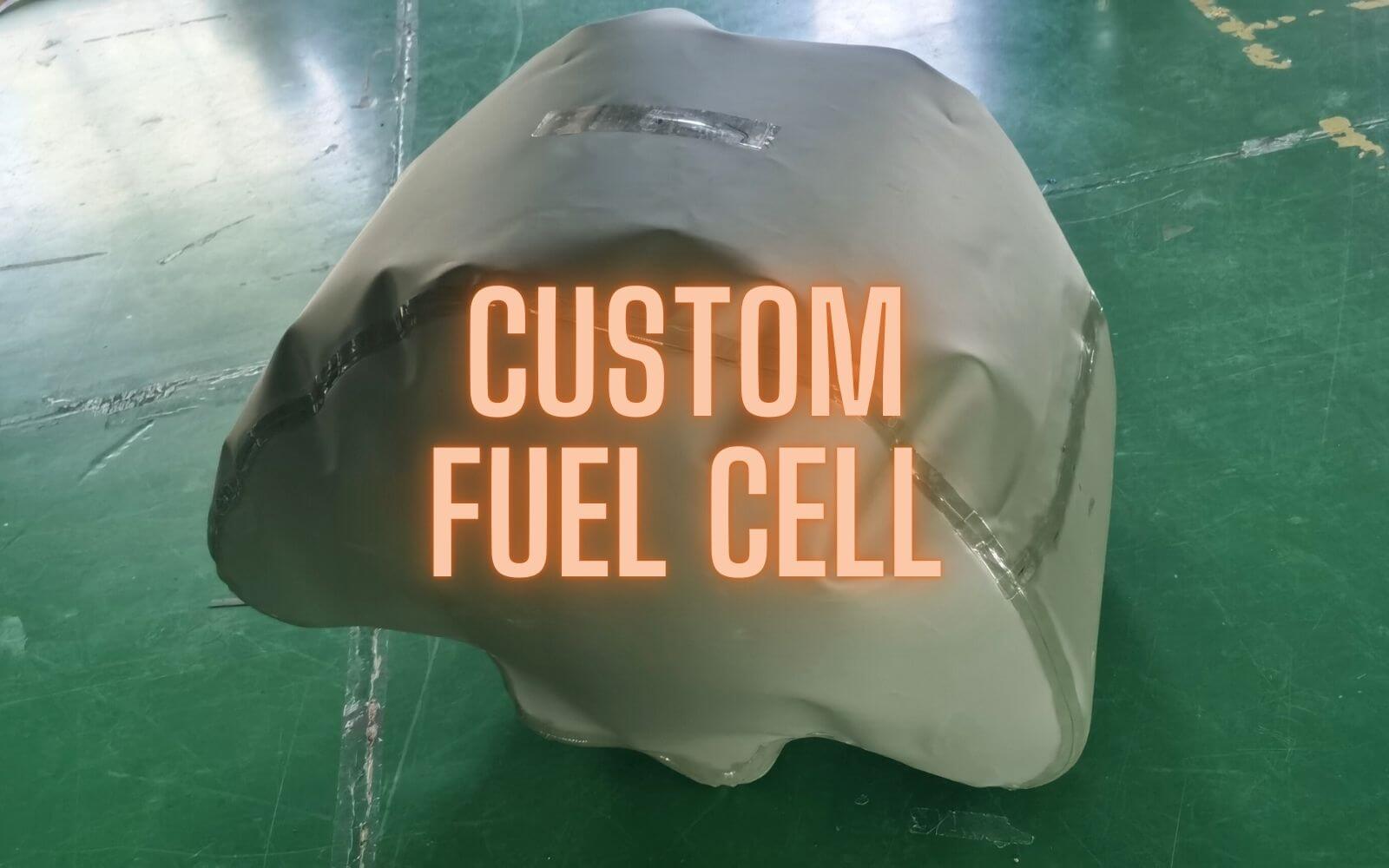

CUSTOM FUEL CELL

Now a day, for fuel storage, innovation is key to enhancing efficiency and functionality. One of the most groundbreaking advancements in this field is the development of flexible custom fuel cells. These custom fuel cells, made from flexible materials, are transforming the way fuel storage and usage, offering unprecedented levels of customization and portability. This article explores how flexible custom fuel cells are revolutionizing fuel storage, emphasizing their ease of customization and portability.

Traditional rigid fuel tanks have long been the standard way for fuel storage in various industries, from automotive to aviation. While effective, these tanks come with limitations, including size constraints, space limited, installation challenges, and weight issues. Enter the flexible custom fuel cell—a game-changer in fuel storage technology.

Flexible custom fuel cells are made from durable, high-quality materials such as polyester-reinforced TPU (Thermoplastic Polyurethane), which allow them to bend and fit into places where traditional rigid tanks cannot reach. The flexibility not only provides more storage options but also makes these fuel cells incredibly adaptable to different applications like: special yacht cabin, aircraft auxiliary fuel storage in limited space, marine fuel transportation, and other applications for fuel storage and transportation.

One of the most significant advantages of flexible custom fuel cells is their easy customization. Whether you need a specific shape, size, or capacity, these fuel cells can be tailored to meet precise requirements. Here’s how customization works:

Tailored Shapes and Sizes:

Flexible custom fuel cells can be manufactured in any shape or size, according to the drawings. This means they can design as your need to fit into irregular spaces, optimizing the use of available space. For example, in the automotive industry, these cells can be molded to fit into the contours of a vehicle’s chassis, maximizing fuel storage without compromising other design elements.

Capacity Adjustments:

Depending on the application’s fuel needs, custom fuel cells can maximize the loading capacity by using any corners of the space. This flexibility is particularly beneficial for industries like marine and aviation, where specific fuel capacity required and must meet with less weight or bulk.

Material Selection:

Different applications may require different materials: the thickness of the materials and the type of the materials, based on the type of fuel stored and environmental conditions. Custom fuel cells can be constructed from materials that are best compatible to their intended use, ensuring durability and safety.

In addition to easy customization, the portability of flexible custom fuel cells sets them apart from traditional options. Here’s why portability matters:

Lightweight Design:

Unlike rigid metal tanks, flexible custom fuel cells are lightweight. This reduces the overall weight of the vehicle or equipment they are installed in, leading to improved performance and fuel efficiency. For instance, in the aviation industry, reducing weight is crucial for enhancing flight efficiency and reducing fuel consumption.

Easy Installation and Removal:

The flexible nature of these fuel cells makes them easy to install and remove. This is particularly advantageous in scenarios where fuel cells need to be frequently moved or replaced. For emergency relief operations, where quick deployment and setup are critical, the portability of these fuel cells is a major asset.

Space-Saving Storage:

When not in use, flexible custom fuel cells can be folded or rolled up, taking up minimal space in store. This feature is ideal for industries where storage space is at a premium, such as marine and military applications.

The versatility of flexible custom fuel cells makes them suitable for a wide range of applications:

Automotive Industry:

Custom fuel cells are being used in performance and racing vehicles to optimize space and improve weight distribution, anti-splash foams added inside to make fuel storage safer. Their flexible design allows for creative placement within the vehicle’s chassis.

Aviation:

In aircraft, reducing weight and optimizing space are critical. Flexible fuel cells can design to fit into wing structures or other unconventional spaces, perfectly fits the space for additional fuel storage, increasing the aviation range, without unnecessary weight added, one more step to make sure the safety and also enhancing efficient fuel consumption.

Marine:

Boats and ships benefit from the adaptable nature of flexible fuel cells. They can be customized to fit into tight compartments, providing efficient fuel storage without compromising on cargo or passenger space.

Emergency and Military:

For rapid deployment in emergency relief or military operations, portable fuel cells are invaluable. Their lightweight and compact storage capabilities ensure that fuel tanks can easily transport and deploy, making sure to provide reliable fuel supply during emergency situations or at remote places.

Flexible custom fuel cell is revolutionizing the fuel storage industry with their unparalleled customization options and portability. By providing tailored solutions that maximize fuel storage space with minimum weight increased, these innovative fuel cells are enhancing efficiency across various industries.

Whether in automotive, aviation, marine, or emergency applications, the advantages of flexible custom fuel cells are clear. They represent the future of fuel storage, offering a blend of innovation, practicality, and efficiency that traditional rigid tanks simply cannot match. As technology continues to advance, we can expect to see even more groundbreaking developments in the field of custom fuel cells, further solidifying their place as a cornerstone of modern fuel storage solutions.